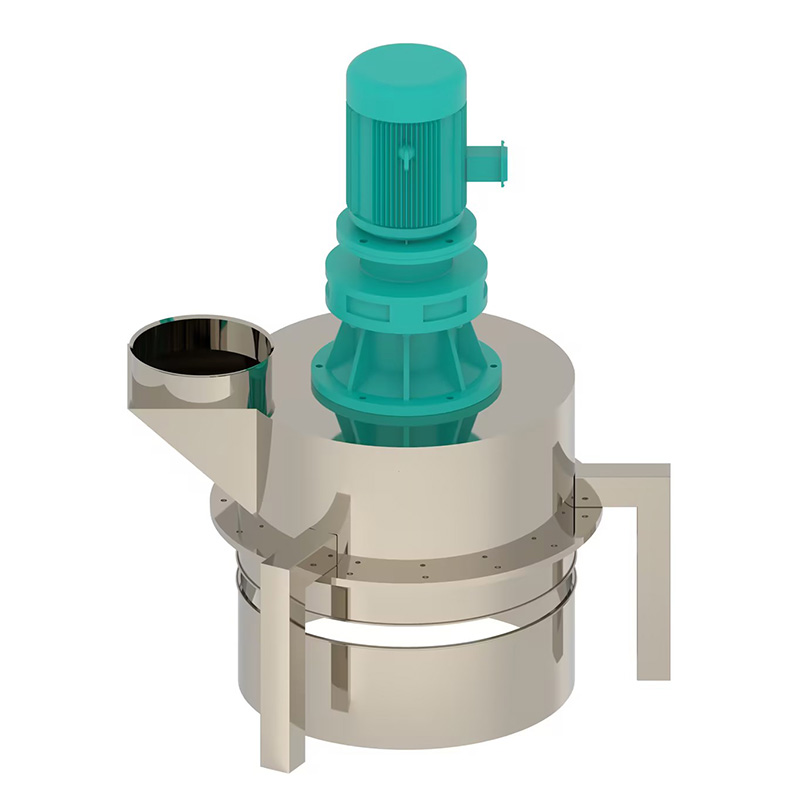

1、 Overview

Flat scraper finished product screen, abbreviated as flat screen, is a continuous cleaning equipment with both crushing functions. The flat screen is composed of an inlet, an outlet, a motor, a scraper, a screen, and a bracket. The material enters the chamber from the feeding port, and the electric motor drives the spindle to rotate. The spindle drives the scraper bracket to rotate, and the scraper bracket drives the scraper to move in a circular motion. The scraper squeezes the powdery material located between the scraper and the flat bottom screen from the screen to the bottom. The agglomerated material is then crushed through processing methods such as pushing, grinding, and squeezing, and then squeezed to the bottom of the screen through the scraper before being discharged. The flat screen is divided into two parts: the upper and lower parts, and a soft connection is used between the lower discharge port and the upper part of the equipment body. The bracket is used to fix the upper part of the equipment body.

TMPBS - (60-80) flat scraper plate finished product screen has a compact structure, convenient production, environmental protection, safety, and economy; Adopting direct transmission, high work efficiency and low energy consumption; The total height of the equipment is about 1 meter, and the diameter of the main shell is 0.6-0.8 meters, which takes up little space and saves space resources; When using the equipment, it is convenient and flexible to replace the screen surface. By opening the access door from the side, the screen surface can be extracted; The agglomerated materials on the sieve that do not meet the particle size requirements will continue to be ground and crushed in the shell until they meet the requirements and are squeezed under the sieve by a flat scraper; Low dust pollution and low noise pollution create a good and comfortable working environment. Less dust is generated, and the incidence of dust explosion accidents is low.

2、 Technical Description

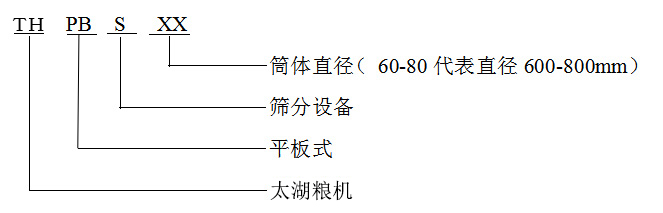

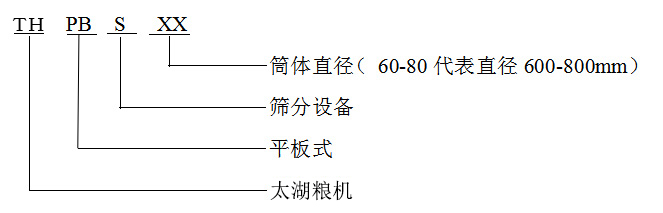

1.Model

2.Technical parameters of flat screen

|

Model

|

PowerP

|

CapacityQ

|

H

|

h

|

D

|

d

|

|

|

KW

|

T/h

|

mm

|

mm

|

mm

|

mm

|

|

TMPBS-60

|

1.5

|

1-3

|

1200

|

600

|

φ940

|

φ600

|

|

TMPBS-80

|

2.2

|

2-5

|

1210

|

600

|

φ1320

|

φ800

|

Note: H-total height of equipment; H - height of the equipment body; D - Equipment body diameter; D - The diameter of the space occupied by the equipment;

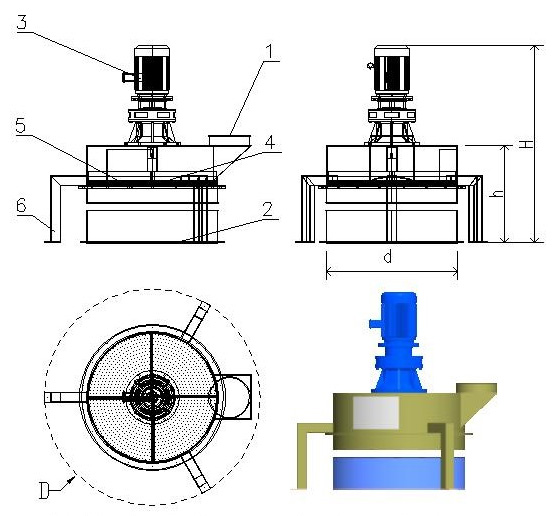

3、 Structural features

Figure 1 shows the ordinary mode of a horizontal spiral machine, which is composed of several parts such as the driving device, electrical equipment, spiral machine body, feeding device, and discharging device. The power end (head) is discharged, and the driven end (tail) is fed.

1. Feed inlet; 2. Discharge port; 3. Motor; 4. Scraper blade; 5. Screen mesh; 6. Bracket;

4、 Installation and debugging

1. Installation of flat screen

The correct installation of the machine is a prerequisite for ensuring good use. The flat screen must be properly installed at the place of use and meet the requirements of this technical condition:

(1)The concrete foundation at the installation site of the flat screen should be poured and hardened at least 20 days before the formal installation of the flat screen. The foundation should be able to reliably support the conveyor and ensure that the flat screen does not sink or undergo additional changes due to the small foundation, ensuring sufficient stability during operation.

(2)If the foundation is poured with concrete, embedded parts need to be installed to fix the flat screen; If it is a steel structure frame, its support beam needs to correspond to the position of the support legs of the flat screen. Weld column anchor bolts on embedded parts or steel structural beams to fix the flat screen for easy disassembly and maintenance.

(3)Before installing the flat screen, it is necessary to clean the dust and dirt adhered during transportation or unloading, and if necessary, clean the machine parts.

(4)The adjacent casing flange surfaces should be neatly and tightly connected, and the misalignment deviation at the joints on the inner surface of the casing should not exceed 2mm.

(5)Due to the continuous operation of the flat screen, soft connections should be used at both the inlet and outlet to enhance the screening effect, reduce mechanical damage, and extend the service life of the equipment.

2.Adjustment of flat screen

(1)The connection of each component of the flat screen should be reliable, without serious misalignment, and the misalignment deviation should not exceed 2mm. During installation, the position of the support legs must be adjusted to correspond to the position of the embedded parts or steel structural beams. At the same time, the upper and lower space should be sufficient to meet the connection of soft connections and the normal use of the equipment.

(2)To adjust the position between the inlet and outlet and the equipment in the upper and lower processes, as well as to prevent wear and collision caused by smooth operation of the equipment, soft connections must be used between the inlet and outlet and the equipment in the upper and lower processes during installation. The soft connections must be made of waterproof coarse canvas.

(3)When the difference between the center of the low-speed shaft of the drive device reducer and the center shaft of the flat screen cylinder is too large, a gasket can be used to adjust the coaxiality.

(4)During the no-load test run, if oil leakage is found in the bearing, the bearing should be removed and the tension of the spring inside the sealing ring adjusted until there is no oil leakage.

(5)The total duration of the no-load test run should be greater than 1 hour. The temperature rise of each bearing during the no-load test run should not exceed 20 ℃. If the temperature rise is too high, it indicates that the position of the suspension bearing is not installed properly, causing jamming of the connecting shaft. The fastening bolts should be loosened and the position of the suspension bearing should be adjusted. During the load test run, the temperature rise of each bearing should not exceed 30 ℃.

5、Use and maintenance of flat screen

Flat screen is a general purpose cleaning and screening equipment used to clean powdery and small materials. Various bearings work in dust, so the reasonable operation and maintenance of flat screen under such working conditions have greater significance. The main requirements for the operation and maintenance of flat screen are as follows:

1.The flat screen should be started without load, that is, when there is no material in the casing, it should be started and feed to the flat screen after starting.

2.During the initial feeding of the flat screen, the feeding speed should be gradually increased until the rated conveying capacity is reached. The feeding materials should be evenly distributed, otherwise it may cause blockage of the screening materials and overload of the driving device, leading to premature damage to the entire machine.

3.In order to ensure the requirement of starting the flat screen without load, the feeding of the flat screen should be stopped before stopping, and the operation of the flat screen can only be stopped after all the materials in the casing are completely discharged.

4.The screened material should not be mixed with hard large pieces of material to prevent the scraper bracket from getting stuck, blocking, and subsequently damaging the flat screen.

5.Regularly inspect the working status of each component of the flat screen during use, pay attention to whether the fasteners are loose. If any loose parts are found, immediately tighten the screws and retighten them.

6.Special attention should be paid to whether the connecting screws between the upper and lower cylinders of the flat screen are loose, fallen off, or cut. If such phenomena are found, the machine should be immediately stopped and corrected.

7.The access door of the flat screen should not be removed during machine operation to avoid accidents.

8.If any abnormal phenomenon occurs during the operation of the flat screen, it should be stopped for inspection and troubleshooting, and forced operation is not allowed.

9.The moving parts of the flat screen should be lubricated regularly.

(1)The reducer of the driving device should be equipped with 2 # lithium based grease, 2 # extreme pressure lithium based grease, or 00 # reducer grease, and the oil should be changed every 3-6 months.

(2)Use lithium based lubricating grease in the bearing box of the flat screen, inject 5 grams every half month.

(3)The main shaft and bearings of the flat screen have been soaked in lubricating oil during assembly, and can be lubricated less frequently. Every 3-5 months, the hanging plate bracket and the main shaft are removed, the sealing ring is removed, the main shaft and bearings are immersed in melted grease, cooled with lubricating oil, and reinstalled for use. If the nylon sealing ring is damaged, it should be replaced in a timely manner. After one year of use, it can be maintained again using the above methods to achieve good results.